The world’s most advanced postprocessing software, IMSpost, transforms CAD/CAM cutter location (CL) files into the specific machine (G/M) codes required by NC machines. With a flexible library of standard postprocessors and machine configurations, you can begin to generate NC files immediately.

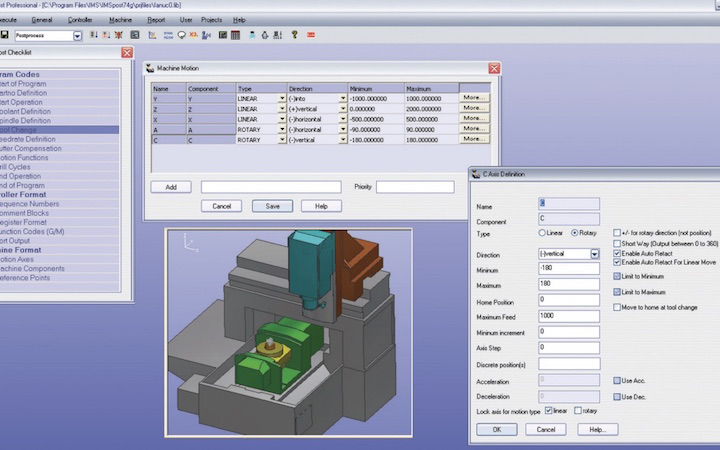

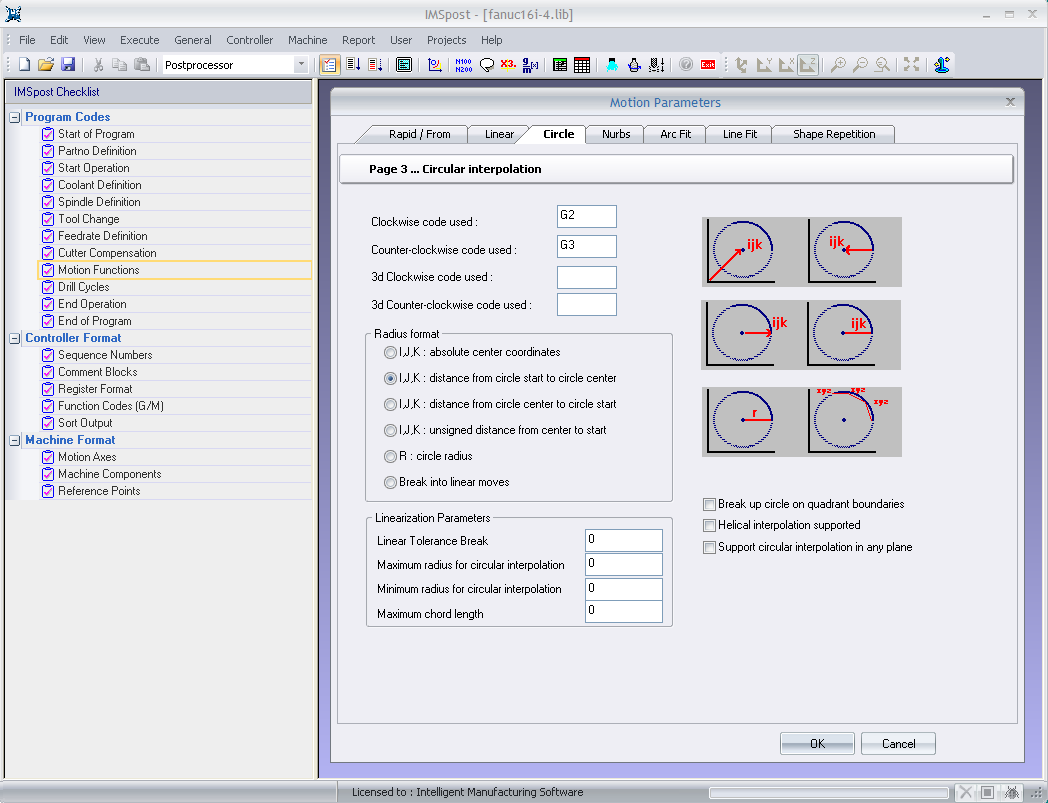

The intuitive IMSpost user interface (with a checklist and Windows GUI) provides an efficient work environment that works seamlessly with all major CAD/CAM systems and hardware platforms. IMS macro processor, with source level debugger, provides support for the most complicated postprocessor configurations.

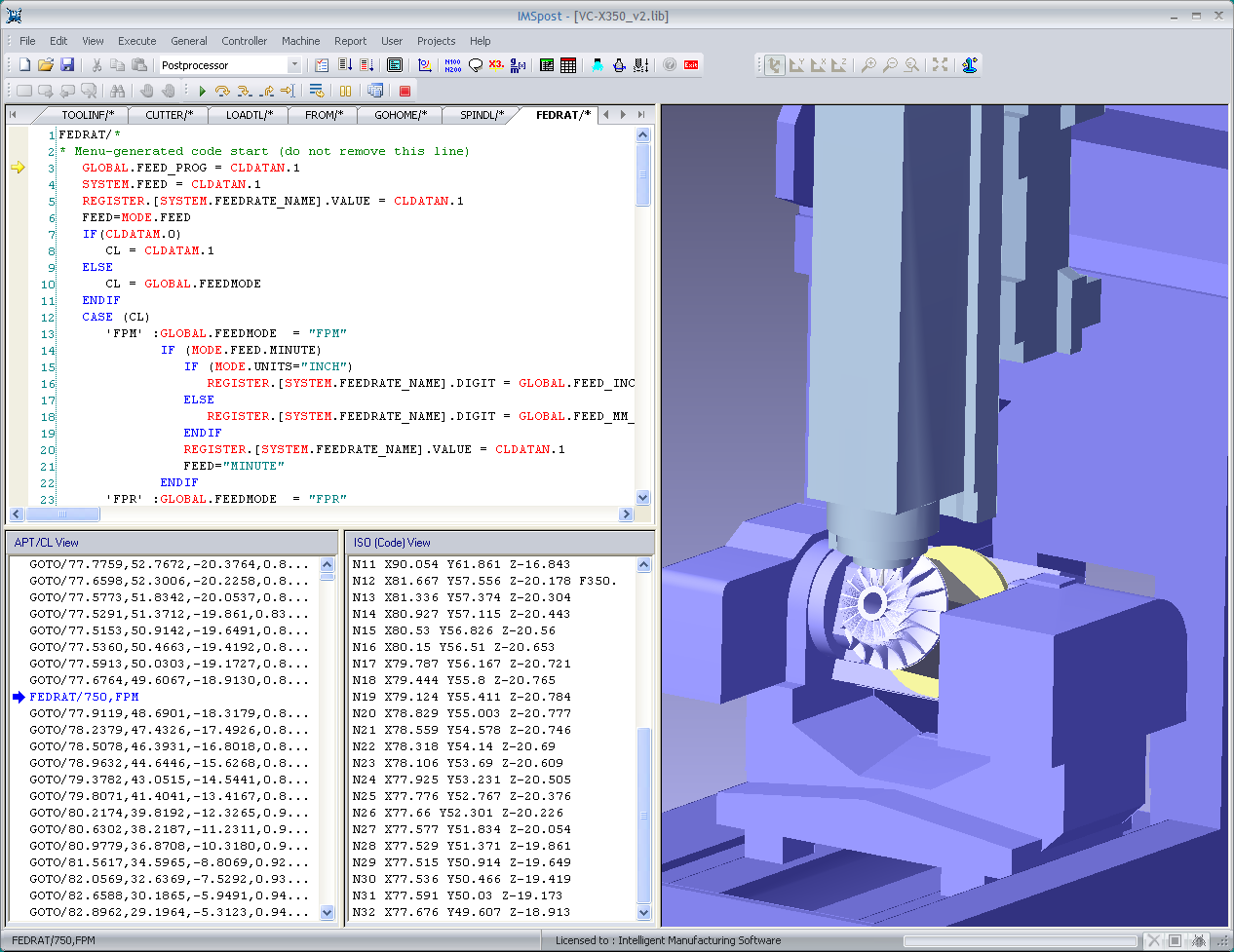

Integrated APT/CL, G-code, and machine view provide the complete picture for CNC post development.

The IMSpost virtual CNC controller offers complete analysis of the machine code and provides a true picture of the tool motion. The virtual controller provides support for NC controls from all major manufacturers.